Some LED fixtures are current controlled (eg. 350mA, 500mA, 700mA and 1050mA). These require a continuous current. To turn the 230V mains voltage into current, you need a separate power supply, a current controlled power supply.

Must be in series circuit

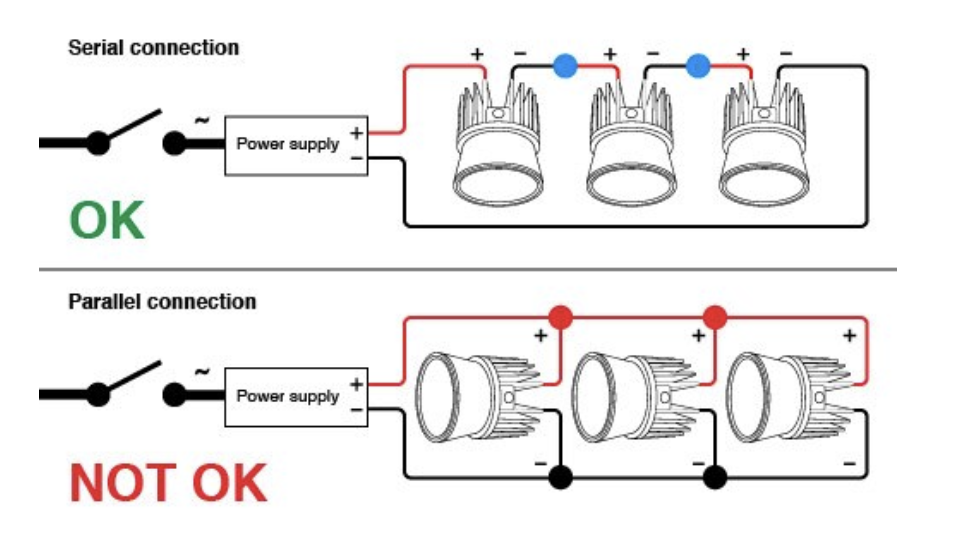

Current controlled LEDs can never be connected under voltage! Furthermore they should always be connected in a series circuit. In series circuits there’s only one current path. The current enters through the + and leaves the spotlight through the + to continue its way to the next spotlight. The current travels in one direction through all spotlights to until they are all under current.

The external power supply needs to be adjusted to the number of spotlights and their power. With a constant current, the voltage will spread equally over the different spots.

Setup simulation

Let’s try to simplify the matter with an example. In this setup, we’re going to install three LED spotlights, each with a power of 6W (AB 38007-350). The spotlights require a continuous current of 350mA.

Calculate required voltage LED spotlight

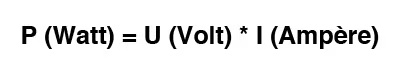

Starting from the formula for electrical power, we can calculate the voltage needed by every separate spotlight. Power equals volts times amps.

Formula for electrical power:

When we turn the formula around, we can calculate the voltage per spotlight:

Every separate LED spotlight needs 17,14V to keep a constant current of 350mA. In total, the three spotlight will need 51,43V (= 3 x 17,14V). The total voltage of the spotlights needs to be within the output reach of the power supply.

So, in this case, a 350mA LED power supply with an output from 40 to 58V, will do just fine. This power supply has a minimal voltage output of 40V and a maximal voltage output of 58V. The total voltage required for the spotlights can’t be over or under the output level of the power supply.

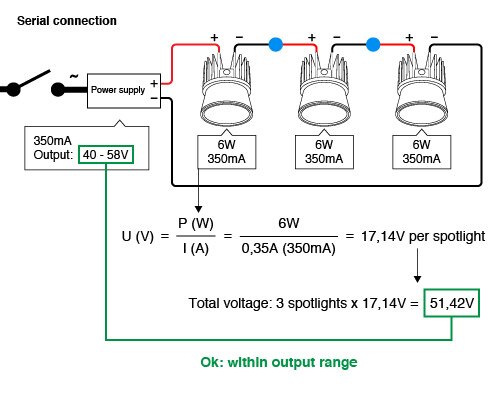

Power supply delivers too much voltage for number of spots:

Let’s say you want to connect only one 6W spotlight, you’ll only need 17,14V. this is lower than the 40V minimal voltage of the power supply. This will result in a defect in the spotlight, because the voltage is too high.

The entire circuit of spotlights always needs to be tested at once. When the installer tests the power supply with each spotlight separately, the spotlight, which requires only 17,14V, immediately receives the full 40V minimum voltage. This too much, so the spot will malfunction.

Power supply delivers too little voltage for number of spots:

When you connect 8 of these 6W spotlights to the same power supply, you’ll need a total current of 137,14V (= 8 x 17,14V). This is higher than the maximal voltage of the power supply. The LED spotlights won’t reach their full luminous efficiency. In other words, they will look ‘dimmed’.

Minimum and maximum number of spots on power supply

For this 350mA power supply (40 - 58V) you need to install at least three of these 6W spotlights. The maximum capacity of the power supply is 3 of these spotlights. In case you want to install more of them, you’ll need a power supply with a higher output.

Never install current controlled LED spotlights under voltage

During the installation of current controlled LED spotlights, the LED power supply may never be under voltage! Neglect this and you’ll risk damaging the LEDs. You’ll even lose your warranty by doing so. In case of doubt, contact a professional electrician.

When LED power supplies are put under voltage, they start looking for the amount of voltage they need to distribute. When there are no spotlights connected, most power supplies will keep building up voltage up to their maximum.

If you connect a LED spotlight to this fully charged power supply, it will immediately receive the maximum output voltage. If this is higher than the maximum voltage of the LED spotlight, the LED will get damaged. It only takes a split second to make this happen.

So, it’s extremely important to switch off the voltage on your power supply while installing your LED spotlights.

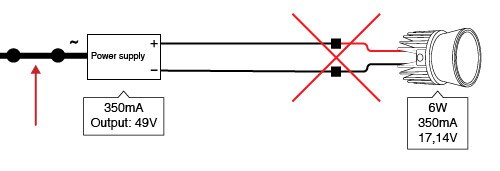

Wrong installation:

Suppose we put a 700mA power supply under voltage. Then, we connect a 6W LED spotlight.The spotlight will immediately get the full 49V output. The maximum voltage for this 6W spotlight is only 17,14V (= 6W / 0,35A), so the LED will get damaged.

You need to connect all your LEDs in advance, before putting your power supply under voltage. This way the power supply can build up to the required voltage.

The power supply can only be switched on the primary side i.e. before the 230V mains voltage comes in. Otherwise the LED will get damaged, just like in the situation above.

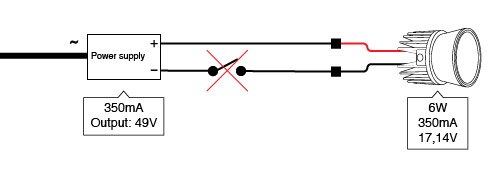

Secured LED power supplies:

Some power supplies are secured against the above phenomenon. When this kind of power supply is put under voltage and no spotlights are connected, they won’t give off their maximum voltage. Instead, they won’t distribute any voltage at all.

The power supply will only start distributing voltage when the spotlights are connected and the power supply is restarted.